Diatomite filter aid has good microporous structure, adsorption performance and anti-compression performance, which not only enables the filtered liquid to obtain a better flow rate ratio, but also filters out fine suspended solids to ensure clarity.

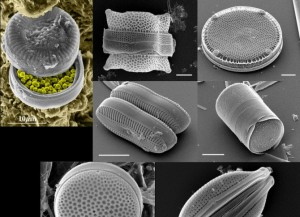

Diatomaceous earth is the deposit of the remains of ancient single-celled diatoms. Its characteristics: light weight, porous, high strength, wear resistance, insulation, heat insulation, adsorption and filling and other excellent performance. Has good chemical stability. It is an important industrial material such as heat insulation, grinding, filtration, adsorption, anti-coagulation, demoulding, filling, carrier and so on. It can be widely used in industries such as metallurgy, chemical industry, electric power, agriculture, fertilizer, building materials and insulation products. It can also be used as industrial functional fillers for plastics, rubber, ceramics, and paper making.

of the remains of ancient single-celled diatoms. Its characteristics: light weight, porous, high strength, wear resistance, insulation, heat insulation, adsorption and filling and other excellent performance. Has good chemical stability. It is an important industrial material such as heat insulation, grinding, filtration, adsorption, anti-coagulation, demoulding, filling, carrier and so on. It can be widely used in industries such as metallurgy, chemical industry, electric power, agriculture, fertilizer, building materials and insulation products. It can also be used as industrial functional fillers for plastics, rubber, ceramics, and paper making.

Diatomite filter aid classification Diatomite filter aids are divided into dried products, calcined products and flux calcined products according to different production processes.

①Dry product The purified, pre-dried and pulverized dry silica clay raw material is dried at a temperature of 600-800°C, and then pulverized. This product has a very fine particle size and is suitable for precision filtration. It is often used in conjunction with other filter aids. The dry product is mostly light yellow, but also milky white and light gray.

②Calcined products The purified, dried and crushed diatomite raw materials are fed into a rotary kiln, calcined at a temperature of 800-1200°C, then crushed and classified to obtain calcined products. Compared with dry products, the permeability of calcined products is more than three times higher. The calcined products are mostly light red.

③Flux calcined products After purification, drying and crushing, the diatomite raw material is added with a small amount of sodium carbonate, sodium chloride and other flux materials, and then calcined at a temperature of 900-1200°C. After crushing and particle size classification and proportioning, the flux calcined product is obtained. . The permeability of the flux calcined product is significantly increased, which is more than 20 times that of the dry product. The flux calcined products are mostly white, and light pink when the Fe2O3 content is high or the amount of flux is small.

Diatomite filter aid filtering effect

The filtering effect of diatomite filter aid is mainly carried out through the following three functions:

1.Sieving effect

This is a surface filtering effect. When the fluid flows through the diatomaceous earth, the pores of the diatomaceous earth are smaller than the particle size of the impurity particles, so that the impurity particles cannot pass through and are intercepted. This effect is called sieving. In fact, the surface of the filter cake can be regarded as a sieve surface with an equivalent average pore size. When the diameter of the solid particles is not less than (or slightly less than) the diameter of the pores of the diatomite, the solid particles will be “sifted from the suspension”. Separate out, play the role of surface filtration.

2. Depth effect

The depth effect is the retention effect of deep filtration. In deep filtration, the separation process only occurs in the “inside” of the medium. Part of the relatively small impurity particles that penetrate the surface of the filter cake are blocked by the tortuous microporous channels inside the diatomaceous earth and the smaller pores inside the filter cake. This kind of particles are often smaller than the micropores of diatomaceous earth. When the particles hit the wall of the channel, they may leave the liquid flow. However, whether it can reach this point depends on the inertial force and resistance of the particles. Balance, this kind of interception and screening are similar in nature, both belong to mechanical action. The ability to filter out solid particles is basically only related to the relative size and shape of the solid particles and pores.

The adsorption effect is completely different from the above two filtration mechanisms. This effect can actually be regarded as an electrokinetic attraction, which mainly depends on the surface properties of the solid particles and the diatomaceous earth itself. When particles with small internal pores in diatomaceous earth collide on the inner surface of porous diatomaceous earth, they are attracted by opposite charges, or the particles attract each other to form clusters and adhere to the diatomaceous earth. These are all adsorption effect.

The adsorption effect is more complicated than the previous two effects. It is generally believed that the reason why solid particles smaller than the pore diameter are trapped is mainly due to:

(1) Intermolecular forces (also called van der Waals attraction), including permanent dipole, induced dipole and instant dipole;

(2) The existence of Zeta potential;

(3) Ion exchange process.

Post time: Jul-14-2021